Fuselage – Center Section – Riveting

Completed deburring of F-1204D Center Section Aft Bulkhead and riveted it to the F-1204 Center Section Assembly along with the smaller bits and pieces.

The pneumatic squeezer I purchased recently on ebay turned out to be useless on rivets longer than 470AD4-7

So most of the solid rivets have been squeezed by hands. The solid rivets come up quite good. I’m happy with them.

There is a very small task at the end of assembly – set 8 CherryMax rivets for F-1204T-L and F-1204U-L Skin Stiffeners and F-1204T-R and F-1204U-R Skin Stiffeners.

These rivets turned to be most challenging to set at the ends of the stiffeners because it is hard to maintain correct position of the rivet puller due to interference from the other parts. VANs only give 2 extra rivets and I managed to screw-up 3.

Because the puller is not perpendicular the stem of the rivet breaks off too early. Correct position of the stem is vital for Cherry rivets. So I need to buy a few of CR3213-4-5 rivets and get that last stuffed up rivet redone.

Anyway, I was nice 4 hours session. Other than this setback with the CherryMax rivets, the section 20 is completed

Update:

I have sent a question to VANs support about the bad CherryMax rivet. They confirmed my suspicions – it needs to be removed and set properly.

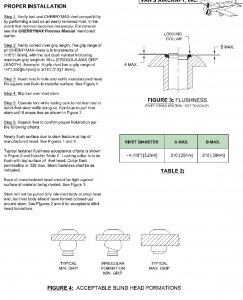

They even sent me the snippet of the document outlining the riveting procedures and tolerances.

I have carefully removed the rivet and set a new one. The mandrel broke off just a little early – about 0.32mm below the top of manufactured head, which is within the range (0.38mm). Due to the nature of the CheriMax rivets repeated replacement with the same size rivet is not recommended. My next attempt would be with oversized rivet. Since this one is within the limit (although not perfect), I decided to leave it alone and move on.

Leave a Reply