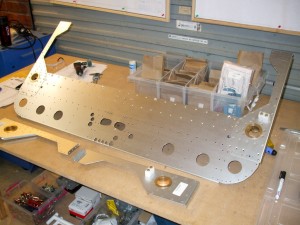

Fuselage – Center Section

Finally started working on the fuselage.

Deburred the assemblies

Installed platenuts and retainers.

While installing retainer on the assembly(Step 3 Page 20-02) found that the hole are dimpled slightly and it wouldn’t let the nut and the washer sit properly. So I used rivet shaver to remove the metal around the hole to make the area flat.

It feels so good to get back to building!

After I finished for the day I found one less than perfect rivet set at VANs (Center section assembly had a few things riveted at the factory)

I can remove the rivet and set a new one – no problem. My concern though is the fine lines around the shop heads of the rivets. I need to ask around.

Update: I asked VANs support and here is the snip of their reply “…the rivet is already doing about 90-95% of a perfect one, so replacing it won’t have any real effect.

The fracture lines occur whenever a rivet is set against an anodized surface. It’s just in the anodized layer, not in the actual metal, and makes no difference to the airplane. No need to do anything.”

I’m moving on!

Leave a Reply